|

产品分类 |

|

|

|

|

|

|

首页 - 产品展厅 - 产品介绍 |

|

|

|

| |

产品名称: |

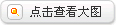

抗硫安全阀 |

| |

产品型号: |

KA41Y |

| |

|

| |

|

| |

咨询电话:021-51061290 李工 张正 |

|

|

|

抗硫安全阀概述:抗硫安全阀是受压设备、容器或管路上的最佳超压保护装置。当设备压力升高达到预定值时,安全阀自动开启,继而全量排放,防止设备压力继续升高;当压力降低到规定值时,安全阀及时自动关闭。抗硫安全阀是选用者为保护工程设备安全运行的最理想的,最科学的明智选择。

|

型 号 |

公称 |

主要结构尺寸(mm) |

阀体

材料 |

简要性能 |

备注 |

|

通径

DN(mm) |

压力PN(MPa) |

D |

D1 |

L |

L1 |

H |

适用温度

℃ |

适用介质 |

|

KA41Y-320P |

15 |

32.0 |

105 |

115 |

95 |

95 |

223 |

1Cr18Ni9Ti |

-40~+130 |

酸性天然气 |

|

|

" |

20 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

25 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

32 |

" |

135 |

165 |

130 |

135 |

334 |

" |

" |

" |

|

|

" |

40 |

" |

|

|

|

|

|

" |

" |

" |

|

|

KA42Y-16C |

32 |

1.6 |

135 |

145 |

115 |

100 |

285 |

铸钢 |

-40~+130 |

酸性天然气 |

|

|

" |

40 |

" |

150 |

160 |

120 |

110 |

278 |

" |

" |

" |

|

|

" |

50 |

" |

165 |

180 |

135 |

120 |

332 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

20 |

215 |

170 |

135 |

478 |

" |

" |

" |

|

|

" |

100 |

" |

220 |

245 |

205 |

160 |

590 |

" |

" |

" |

|

|

" |

150 |

" |

280 |

310 |

255 |

230 |

650 |

" |

" |

" |

|

|

KA42Y-40 |

32 |

4.0 |

140 |

150 |

115 |

100 |

265 |

铸钢 |

-40~+130 |

酸性天然气 |

|

|

" |

40 |

" |

145 |

160 |

130 |

120 |

278 |

" |

" |

" |

|

|

" |

50 |

" |

160 |

180 |

145 |

130 |

332 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

195 |

215 |

170 |

150 |

478 |

" |

" |

" |

|

|

" |

100 |

" |

230 |

245 |

205 |

185 |

590 |

" |

" |

" |

|

|

" |

150 |

" |

300 |

310 |

255 |

230 |

650 |

" |

" |

" |

|

|

KA42Y-64 |

40 |

6.4 |

165 |

160 |

130 |

120 |

305 |

铸钢 |

-40~+130 |

酸性天然气 |

|

|

" |

50 |

" |

175 |

180 |

165 |

130 |

462 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

210 |

230 |

175 |

160 |

574 |

" |

" |

" |

|

|

" |

100 |

" |

250 |

27 |

195 |

195 |

600 |

" |

" |

" |

|

|

KA42Y-100 |

40 |

10.0 |

|

|

|

|

|

铸钢 |

-40~+130 |

酸性天然气 |

|

|

" |

50 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

100 |

" |

|

|

|

|

|

" |

" |

" |

|

|

KA42Y-16P |

32 |

1.6 |

135 |

145 |

115 |

100 |

265 |

1Cr18Ni9Ti |

-40~+130 |

酸性天然气 |

|

|

" |

40 |

" |

150 |

160 |

120 |

110 |

278 |

" |

" |

" |

|

|

" |

50 |

" |

165 |

180 |

135 |

120 |

332 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

200 |

215 |

170 |

135 |

478 |

" |

" |

" |

|

|

" |

100 |

" |

220 |

245 |

205 |

160 |

590 |

" |

" |

" |

|

|

" |

150 |

" |

280 |

310 |

255 |

230 |

650 |

" |

" |

" |

|

|

KA42Y-40P |

32 |

" |

140 |

150 |

115 |

100 |

260 |

1Cr18Ni9Ti |

-40~+130 |

酸性天然气 |

|

|

" |

40 |

" |

145 |

160 |

130 |

120 |

278 |

" |

" |

" |

|

|

" |

50 |

" |

160 |

180 |

145 |

130 |

332 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

195 |

215 |

170 |

150 |

478 |

" |

" |

" |

|

|

" |

100 |

" |

230 |

245 |

205 |

185 |

590 |

" |

" |

" |

|

|

" |

150 |

" |

300 |

310 |

255 |

230 |

650 |

" |

" |

" |

|

|

KA42Y-64P |

40 |

" |

165 |

160 |

130 |

120 |

305 |

1Cr18Ni9Ti |

-40~+130 |

酸性天然气 |

|

|

" |

50 |

" |

175 |

180 |

165 |

130 |

462 |

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

210 |

230 |

175 |

160 |

582 |

" |

" |

" |

|

|

" |

100 |

" |

250 |

270 |

195 |

195 |

600 |

" |

" |

" |

|

|

KA42Y-100P |

40 |

10.0 |

|

|

|

|

|

1Cr18Ni9Ti |

-40~+130 |

酸性天然气 |

|

|

" |

50 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

65 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

80 |

" |

|

|

|

|

|

" |

" |

" |

|

|

" |

100 |

" |

|

|

|

|

|

" | |

|

|

|